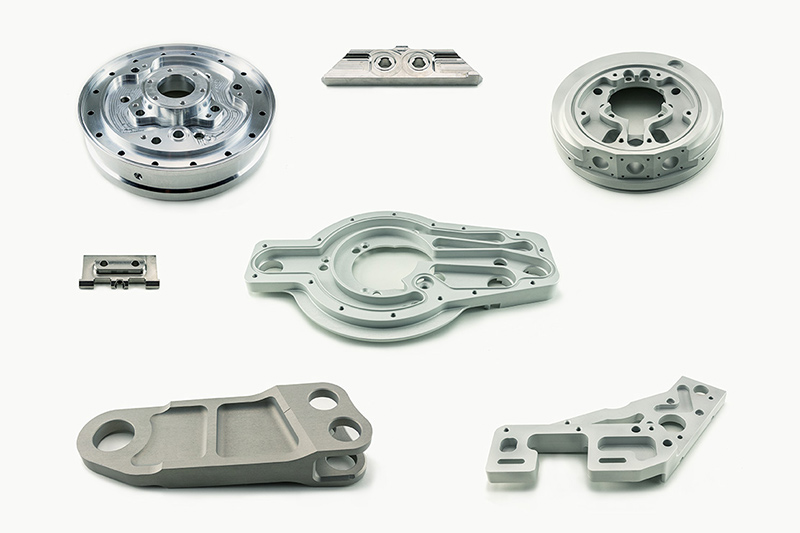

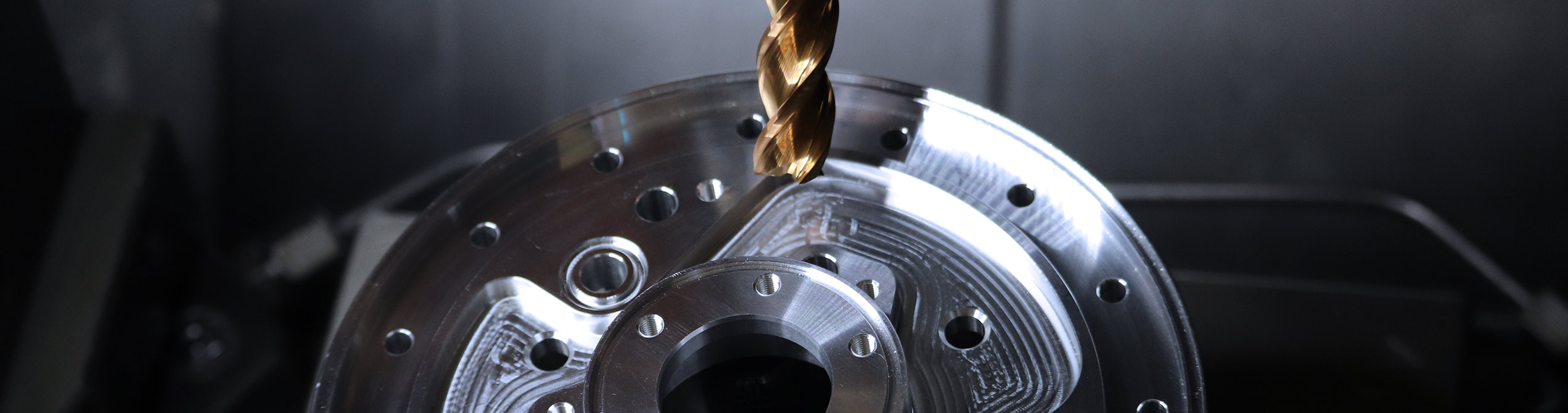

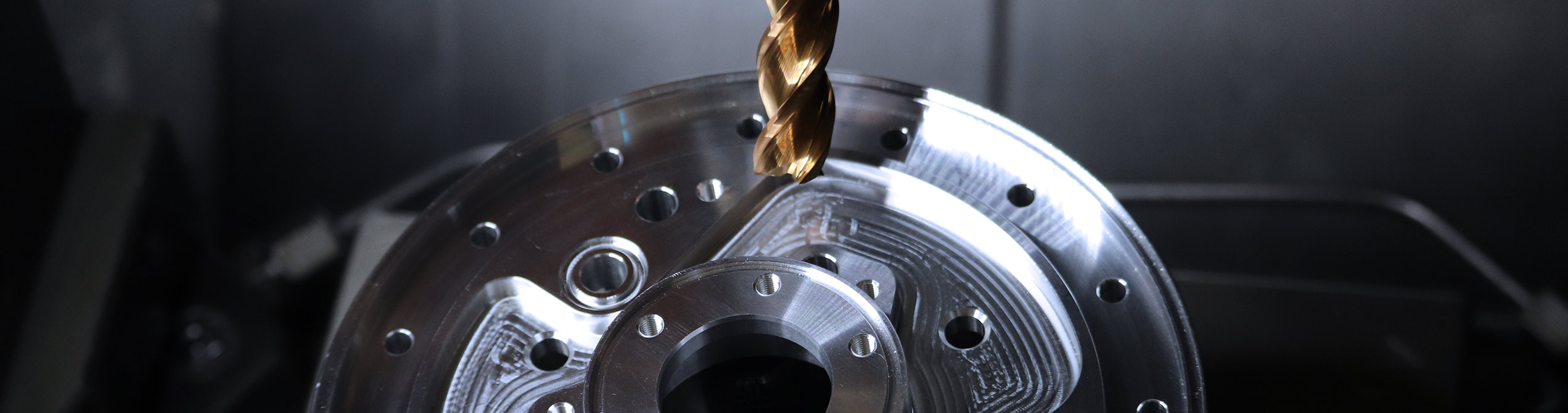

„5-axis simultaneous milling, directly from a 3D model? You’ve come to the right place – for prototypes, short production runs or for volume production!“

Harry Konrad, Technology Project Planning

When we here at Apelt talk of absolute precision, then we mean a level of accuracy that many only know about in theory. Our most commonly used measuring unit is the micron – our processes and procedures are designed around that, and we are very much at home in this métier. People wanting absolute precision come to Apelt.