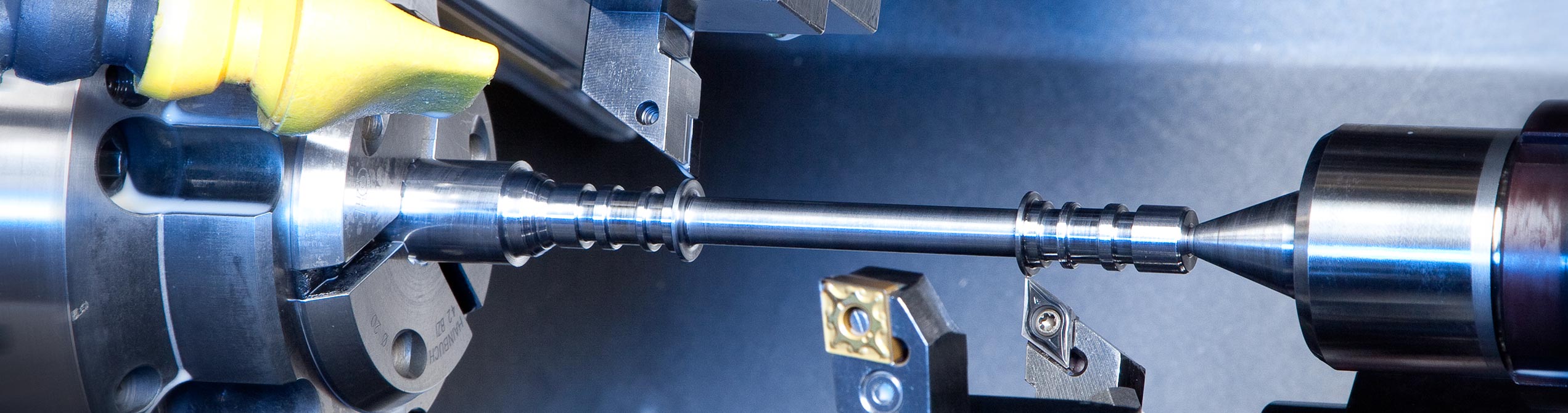

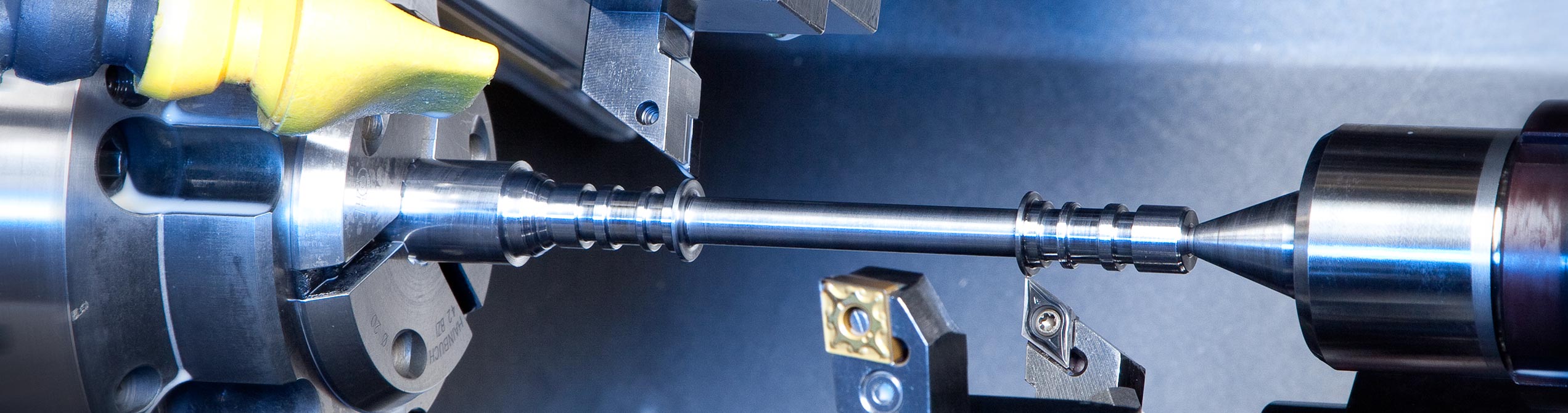

„Whether turning long or short parts,

Uwe Weisser, Production Manager

everything we do revolves around quality.’“

Not every turned part is the same. Anyone who views precision in relative terms can try out many things. Whenever absolute precision is required, all roads lead to Apelt. Our digital processes, from drawing board to turning shop, are designed around absolute precision.

Examples from our component range